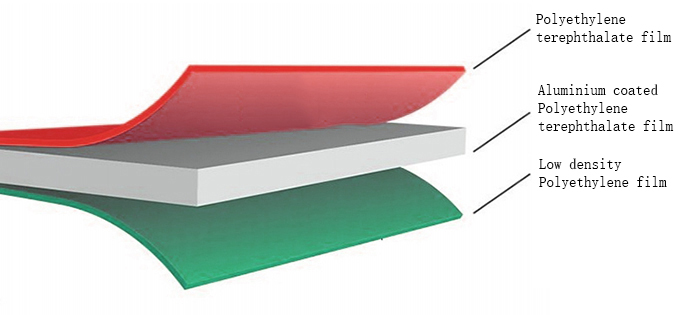

PET/VMPET/LDPE laminates are widely used for packaging pharmaceutical and food materials. With a middle aluminum coated polyester layer, the laminates feature an excellent light resistance and oxygen barrier. The surface is made of a polyester film, which increases the sealing performance and ensures the surface is easily printed on. The inner polyethylene layer ensures the heat sealing process during the bag production is simple, ensuring pouches feature an outstanding heat sealing strength to extend product expiration dates.

Vacuum-metallized Polyester (VMPET)Polyethylene

Common Structures

Key Features

- Excellent air tightness

- Excellent mechanical properties and outstanding rigidity, hardness and toughness.

- A high temperature resistance and low temperature resistance

- Excellent chemical stability and resistance to oil

- Excellent light shading property and UV resistance

- Great water resistance and very good oxygen-resistance.

- Easy to be printed and processed

Parameter

- Water transfer rate≤2.0g/(㎡·24h)

Oxygen transfer rate≤10cm³/(㎡·24h·0.1Mpa)

Peel strength between ≥1.0N/15mm - Heating sealing strentgh≥7.0N/15mm

- Residual quantity of solvent≤5.0mg/㎡

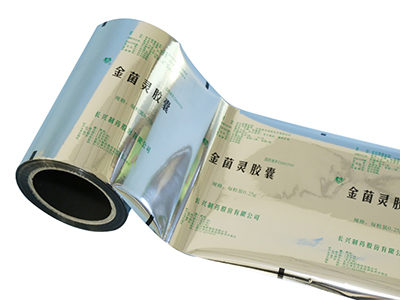

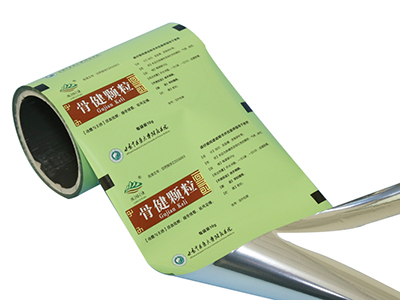

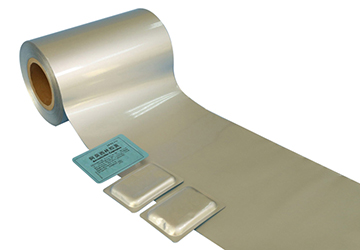

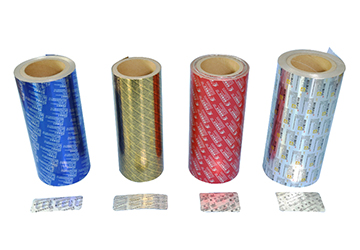

Sample display

HQ is a professional pharmaceuticals flexible packaging manufacturer, we specialize in developing and providing packaging materials according to your product features and packaging requirement, such as laminated films and pouches, matellized films, blister pack materials, etc. If you are looking for a suitable packaging solution, HQ will be your best choice.Contact, Here are our common packaging products, you can also click the following link to know more information.Inquiry

Welcome to HQ Packaging!

Add.: No. 8, Area B, Yangjian Industry Zone, Wuxi City, Jiangsu Province

Fax.: +86-510-88331663